Investing on a good impact wrench is a great idea. Whether you are a professional or a home owner, you can use it both for garage or industrial purposes. Using the tool can streamline tasks, accelerate completion, and significantly enhance efficiency, thereby boosting the company’s overall productivity.

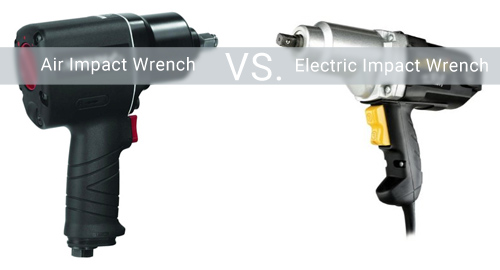

There are a lot of available impact wrenches in the market right now. Let’s highlight the advantages of both Air impact wrenches and Electric impact wrenches

Advantages of Air Impact Wrenches:

- High Torque Output. Air impact wrenches are renowned for delivering exceptional torque output, rendering them ideal for tackling heavy-duty tasks demanding substantial force.

- Compact and Lightweight. These tools are usually more compact and lighter. This enhances maneuverability and ease of use, especially in tight spaces or when working overhead.

- Cost-Effective Startup. Air impact wrenches typically come with a lower initial cost, especially when an air compressor is already available. This affordability makes them a practical and economical option for users who are new to using these tools.

- Quick Torque Delivery. Air impact wrenches provide rapid bursts of torque, enabling efficient and swift tightening or loosening of bolts and nuts.

Advantages of Electric Impact Wrenches:

- Versatile Power Options. Electric impact wrenches are available in diverse power levels, making them suitable for a wide array of tasks. These tasks range from light-duty applications to heavy-duty projects.

- Portability. Cordless electric impact wrenches offer exceptional mobility, enabling usage anywhere without needing a power outlet or air compressor. This makes them an excellent choice for remote or on-the-go work.

- Lower Maintenance. Electric impact wrenches generally require less maintenance compared to their air counterparts. This reduces the need for regular upkeep such as lubrication and filter changes.

- Quieter Operation. Electric impact wrenches operate with less noise and vibration, creating a more comfortable and less disruptive working environment. This quality is especially useful when working in confined spaces where interference needs to be minimized.

Air impact wrenches shine in scenarios requiring significant torque and budget-friendliness. On the other hand, electric impact wrenches provide versatility, portability, and lower maintenance requirements. Your choice between the two will depend on your specific job requirements, available resources, and personal preferences.

Let’s highlight the disadvantages of each.

Disadvantages of Air Impact Wrenches:

- Need for Air Compressor. Air impact wrenches require a reliable air compressor to operate, which adds to the overall cost and setup complexity.

- Limited Mobility. The need for an air compressor limits the mobility of pneumatic wrenches. This makes them unsuitable for remote or on-site work.

- Maintenance Demands. Air impact wrenches and their associated air compressors require regular maintenance, including lubrication, filter changes, and potential compressor upkeep.

- Noise and Vibration. These tools tend to run louder and create more vibration when operating. This can contribute to a less comfortable working environment.

Disadvantages of Electric Impact Wrenches:

- Initial Cost. Electric impact wrenches, especially high-powered or cordless models, often have a higher upfront cost compared to air impact wrenches.

- Limited Battery Life. Battery life limits the capabilities of cordless electric wrenches. This can be a problem when performing long or difficult jobs where there is no access to charging.

- Less Torque for Some Models. Electric impact wrenches encompass a wide spectrum of torque levels. However, they might fall short of reaching the utmost torque outputs of air impact wrenches, particularly in extremely heavy-duty tasks.

- Charging Time. Cordless models require charging time, which can cause delays if the battery runs out during a job and needs recharging.

- Heat Generation. Intensive or prolonged use of electric wrenches can lead to overheating. This may affect performance or require breaks for cooling.

The requirement for a compressor can restrict the capabilities and portability of air impact wrenches. Conversely, electric impact wrenches might come with higher initial costs and potential limitations in terms of torque or battery life. The choice between the two depends on the specific requirements of your tasks and the trade-offs you’re willing to make.

It is very difficult to compare different types of impact wrenches, as each has its own advantages and disadvantages. There has long been a debate about whether a pneumatic impact wrench or an electric impact wrench is better. Below are some points of comparison between the two types in more detail.

Weight of Impact Wrench

Weight is one of the most basic things that consumers pay attention to. Since the portability of the tool depends on it. Generally speaking, an electric impact wrench weighs much less than an air impact wrench. Therefore, users who do a lot of work prefer to use it as they will find it convenient to carry the tool despite working for long hours.

Power of Impact Wrench

It is also very critical to look at the power output of both types because it is the reason why you actually decided to buy one. You need the force that an impact wrench can provide to make your work easier. Both types can produce a very powerful output. However, researchers discovered that an electric impact wrench delivers a higher and consistent level of power. When working on heavy-duty projects, you would want something that would not give up on you in the middle of the task. Since an air impact wrench depends on an air compressor for its power supply, it tends to fluctuate based on the quality of the compressed air delivered by the compressor. However, the large force that an air impact wrench can provide would be an advantage in removing bolts of all sorts. The powerful torque of the air impact wrench makes it very reliable.

Convenience of the Impact Wrench

Having an impact wrench is very convenient in itself already. However, things can be more convenient when you have the right type of wrench that will work best for you. If you have an air compressor that is readily available, you may choose to go with the air impact wrench. However, if you do not have one, it might be better for you to go with the electric impact wrench. With the latter, you will only need an electrical power outlet to use the tool so it would be more convenient. You can use both for assisting with automotive tasks or simple household jobs.

Level of Technology

We all desire our tools to incorporate the latest updates. Air impact wrenches outpace in terms of technological advancement. They boast intricate structures and designs engineered to endure prolonged usage. Electric impact wrenches, on the other hand, has also been improving in terms of high-level technology.

Cost-Effectiveness of the Wrench

If you are working on a tight budget, this is probably one of your biggest considerations. You can purchase most models of impact wrenches at an affordable price. It may seem expensive for some but the quality of service that it provides can definitely justify the price. Considering the need to purchase an air compressor to operate it, an air impact wrench might be perceived as more expensive.To use an electric impact wrench, you do not need to buy any other piece of equipment. This fact alone makes the electric one much less expensive than the air impact wrench.

Portability

This is a big factor for people who are always on the go. Also, most people want to be able to use the wrench for emergency purposes so they want the wrench to be very portable. Both types are lightweight and compact. For electric impact wrench, however, you might not be able to find a power outlet anywhere you go. Thus, you would not be able to use it. On the other hand, for an air impact wrench, you can use it as long as your air compressor is also portable. If you have a huge air compressor, you cannot bring it with you.

Impact Wrench Noise

Although this is a minor detail, it is very important for home owners who value quiet operations to avoid disturbing other people who may be sleeping or working also. An electric impact wrench is quieter than a pneumatic wrench already because you can’t hear the noise of the air compressor in the background. Your family and neighbors would definitely appreciate if you will be able to lessen the noise that your tool produces.

These are just some of the factors that you need to take a look at. As you can see, each type of wrench provides pros and cons that need careful consideration. The buyer should weigh these options and choose wisely so as to avoid wasting time, money, and effort.

One of the things that the buyer can do is to determine the types of activities that he/she will be doing so that he/she can identify what will work best for him/her. It becomes much easier when you know the purpose of why you are buying something. Don’t worry, because regardless of your choice, each of them will reduce your burden and make your life easier.

You may also search online and read for feedback and reviews of the two types of impact wrench. They can be considered as reliable because they already have a first-experience in using the tools. Be careful though because some are just trolls in the internet. Make sure that you sift through the comments that will affect your decision-making process. A lot of websites offer detailed explanations on the specifications of a certain tool so you do not have to worry because this task is simple.

If you already used these two tools and want to share your opinion about comparison of the Air Impact Wrench vs Electric Impact Wrench, feel free to do this through the form below